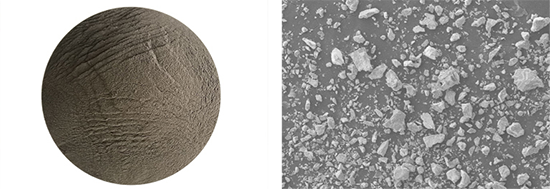

Milled Ferrosilicon 15% is manufactured by melting ferrosilicon 75% and

steel scrap in an induction furnace furnace. The molten alloy is tapped into a

sandbed, allowed to cool, and then broken into lumps, after which it is crushed

in two stages and milled and air classified to the required size

range.

Material Data Sheet

Fe: 80% min, Si: 14-16%, Mn: 0.8% max, Cr: 0.6% max, Cu: 0.5% max,

P: 0.10% max, S: 0.05% max

Particle Size Distribution

| Grade | 48D | 65D | 100D | 150D | 270D |

| +212 (microns) | 0-2 (%) | 0-1 | 0-1 | 0-1 | 0 |

| -212+150 | 4-8 | 0-3 | 0-1 | 0-1 | 0 |

| -150+106 | 12-18 | 4-8 | 1-4 | 0-2 | 0-1 |

| -106+75 | 19-27 | 9-17 | 5-10 | 2-6 | 0-3 |

| -75+45 | 20-28 | 24-32 | 20-28 | 13-21 | 7-11 |

| -45 | 27-35 | 47-55 | 61-69 | 73-81 | 85-93 |

Non-Magnestics: 1.5% Max

Density: 6.7-7.1

Packing: 1mt, 2mt, or iron drums as per request