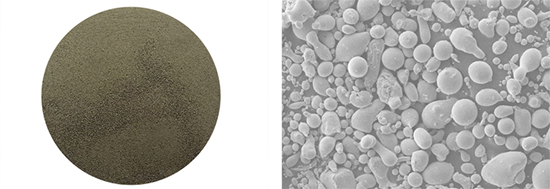

Atomised ferrosilicon 45% is manufactured by melting fesi 75% ferrosilicon

with premium scrap steel in an induction furnace. The melt is then blown into

small particles by high pressure water jetting system. It is then dried and

sieved into different grades and packaged as per customer’s request.

Atomised ferrosilicon 45% is mainly used for welding industries for the

manufacturing of welding electrode.

Material Data Sheet

Si: 43-47% ,Al: 1.0% max, Mn: 0.5% max, C: 0.1% max, P: 0.05% max

S: 0.04% max, Cr : 0.3% max, Fe : rest

PARTICLE SIZE (cumulative % above)

| Sieve (mm) | Min | Max |

| 0.355 | 0 | |

| 0.150 | 20 | 50 |

| 0.063 | 60 | 90 |

| 0.045 | 75 | 95 |

Sizing can be adjusted at customer’s request

Packing: 1mt, 2mt, or iron drums as per request