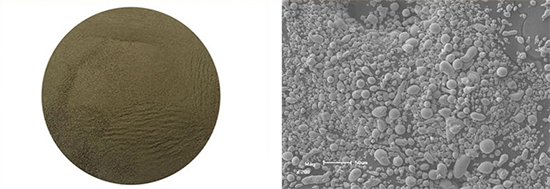

Atomised ferrosilicon 15% is manufactured by melting fesi 75% ferrosilicon

with premium scrap steel in an induction furnace. The melt is then blown into

small particles by high pressure water jetting system. It is then dried and

sieved into different grades and packaged as per customer’s request.

Atomised fesi has the following properties:

(a) resistance to abrasion,

(b) resistance to corrosion,

(c) high specific gravity,

(d) magnetism, which allows easy magnetic recovery with subsequent easy

demagnetization

Material Data Sheet

Fe: 80% min, Si: 14-16%, Mn: 0.8% max, Cr: 0.6% max, Cu: 0.5% max,

P: 0.10% max, S: 0.05% max

Particle Size Distribution

| Grade | coarse | fine | cyclone 60 | cyclone 40 |

| +212 (microns) | 2-4 (%) | 1-3 | 0-0 | 0-0 |

| -212+150 | 5-9 | 3-7 | 0-1 | 0-0 |

| -150+106 | 11-15 | 8-12 | 0-3 | 0-0 |

| -106+75 | 15-21 | 13-17 | 2-4 | 1-3 |

| -75+45 | 20-26 | 19-25 | 20-24 | 10-14 |

| -45 | 32-42 | 42-50 | 68-78 | 82-90 |

Non-Magnestics: 0.5% Max

Density: 6.7-7.1

Packing: 1mt, 2mt, or iron drums as per request